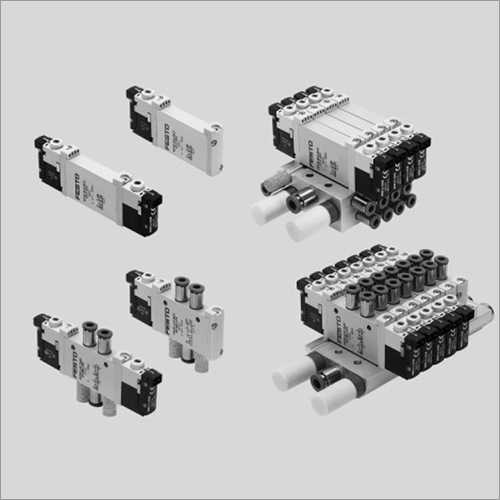

Pnuematic Cylinder

Product Details:

- Power Pneumatic (compressed air driven)

- Structure Double Acting, ISO standard round or square body

- Media Filtered, lubricated or non-lubricated compressed air

- Material Aluminum with stainless steel piston rod

- Air Consumption 0.25 cfm to 1.5 cfm (varies with size and pressure)

- Speed 50 to 500 mm/sec

- Maximum Torque N/A (typically measured as force; can range up to 5000 N for heavy-duty cylinders)

- Click to View more

X

Pnuematic Cylinder Price And Quantity

- 1 to 10 bar

- Adjustable pneumatic cushioning at both ends

- 32 mm (can vary from 12 mm to 100 mm depending on model)

- Automation, packaging, printing, clamping, material handling

- 25 mm to 500 mm (customizable)

- 1/8" to 1/2" BSP (varies per size)

- Front and rear flange, foot, or clevis mountings

- -20°C to 80°C

- NBR (Nitrile Rubber), Polyurethane

- Aluminium with anodized finish

Pnuematic Cylinder Product Specifications

- Pneumatic (compressed air driven)

- 0.25 cfm to 1.5 cfm (varies with size and pressure)

- Aluminum with stainless steel piston rod

- Filtered, lubricated or non-lubricated compressed air

- N/A (typically measured as force; can range up to 5000 N for heavy-duty cylinders)

- 50 to 500 mm/sec

- Double Acting, ISO standard round or square body

- 1 to 10 bar

- Adjustable pneumatic cushioning at both ends

- 32 mm (can vary from 12 mm to 100 mm depending on model)

- Automation, packaging, printing, clamping, material handling

- 25 mm to 500 mm (customizable)

- 1/8" to 1/2" BSP (varies per size)

- Front and rear flange, foot, or clevis mountings

- -20°C to 80°C

- NBR (Nitrile Rubber), Polyurethane

- Aluminium with anodized finish

Product Description

Experience the magnificent blend of robust engineering and fresh innovation with our Pneumatic Cylinder, expertly crafted for automation, packaging, and material handling. Its bore size ranges from a nimble 12 mm up to an immaculate 100 mm, while stroke length is fully customizable from 25 mm to 500 mm. Procure this venerable solution featuring adjustable cushioning, an anodized aluminium end cap, and reliable NBR/polyurethane seals. The cylinder boasts a bargain in durability and efficiency, suitable for diverse operating conditions (pressure: 1-10 bar, temperature: -20C to 80C) and mounting options. Supplied by seasoned manufacturers and exporters in India.

Why Choose Our Pneumatic Cylinder?

Our pneumatic cylinder offers outstanding versatility, making it adept for automation, printing, clamping, and material handling. Thanks to adjustable pneumatic cushioning and immaculate mounting flexibility via front/rear flange, foot, or clevis, it ensures magnificent performance with every use. Special features include polyurethane/NBR seals for extended lifespan and anodized aluminium for corrosion resistance. Ideal for environments that demand reliablity and speed, it holds up under variable air pressure and temperature.

Sample, Packaging, and FOB Details

Sample cylinders are available for evaluation, handed over to clients upon request with a nominal charge. Each product is carefully packaged to ensure immaculate arrival-whether singularly boxed or in bulk packaging. For export transactions, we operate through reliable FOB Indian ports, expediting handover and arrival at your destination with seamless process efficiency.

Why Choose Our Pneumatic Cylinder?

Our pneumatic cylinder offers outstanding versatility, making it adept for automation, printing, clamping, and material handling. Thanks to adjustable pneumatic cushioning and immaculate mounting flexibility via front/rear flange, foot, or clevis, it ensures magnificent performance with every use. Special features include polyurethane/NBR seals for extended lifespan and anodized aluminium for corrosion resistance. Ideal for environments that demand reliablity and speed, it holds up under variable air pressure and temperature.

Sample, Packaging, and FOB Details

Sample cylinders are available for evaluation, handed over to clients upon request with a nominal charge. Each product is carefully packaged to ensure immaculate arrival-whether singularly boxed or in bulk packaging. For export transactions, we operate through reliable FOB Indian ports, expediting handover and arrival at your destination with seamless process efficiency.

FAQ's of Pnuematic Cylinder:

Q: How do I select the right bore size and stroke length for my application?

A: Begin by assessing your force and space requirements within your intended application. Our pneumatic cylinders offer bore sizes from 12 mm to 100 mm and customizable stroke lengths from 25 mm to 500 mm, enabling tailored solutions for various automation and material handling needs.Q: What special cushioning features are available in the pneumatic cylinder?

A: Each cylinder is equipped with adjustable pneumatic cushioning at both ends, which allows for smooth deceleration and protection from impact, ensuring longevity and efficient operation in high-speed applications.Q: Where can these pneumatic cylinders be used?

A: These cylinders are suitable for use in automation, packaging, printing, clamping, and material handling sectors, fitting processes that require precise control, rapid actuation, and consistent performance even under demanding conditions.Q: When are samples available and how are they provided?

A: Sample units can be handed over upon client request, usually after processing a nominal fee. Packaging is tailored for safety during transit and arrival at the destination, with shipping arranged from reliable FOB Indian ports.Q: What are the key maintenance benefits for this pneumatic cylinder?

A: The cylinder's construction, featuring polyurethane/NBR seals and an anodized aluminium end cap, promotes enhanced durability and resistance to corrosion, reducing the need for frequent maintenance. Usage of filtered/lubricated compressed air helps prolong operating life and maintains optimal performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Festo Mta Pneumatics' category

|

J K ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |